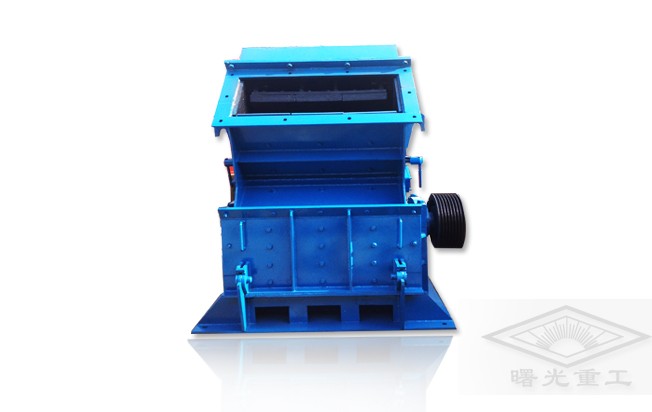

Product details

Application:

Hammer crusher is widely used in fine grinding medium hardness materials in industrial departments such as concentrating plants, refractory plants, cement plants and glass factories. It can be used for dry and wet crushing. The wet type is to wet the material by water seepage, while the dry type does not allow water to be used for dry grinding.

Working principle:

The motor drives the rotor to rotate at high speed in the crushing chamber, and the material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing and grinding action of the high-speed moving hammer. In the lower part of the rotor, a sieve plate is arranged, and the size of the pulverized material smaller than the mesh size is discharged through the sieve plate, and the coarse-grained grade larger than the mesh size is retained on the sieve plate and continues to be struck and ground by the hammer, and finally passed through the sieve plate. Discharge outside the machine.

Structure:

The main working part of the hammer crusher is a rotor with a hammer (also called a hammer). The rotor consists of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feed port, and is crushed by the impact, impact, shearing and grinding action of the high-speed moving hammer. In the lower part of the rotor, a sieve plate is arranged, and the size of the pulverized material smaller than the mesh size is discharged through the sieve plate, and the coarse-grained grade larger than the mesh size is retained on the sieve plate and continues to be struck and ground by the hammer, and finally passed through the sieve plate. Discharge outside the machine.

Previous page:Jaw crusher

Next page:Bucket elevator

TEL:0086-13523465141

0086-371-67666660

FAX:0086-371—68125111

Email:shuguang_mill@163.com

Address:No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China