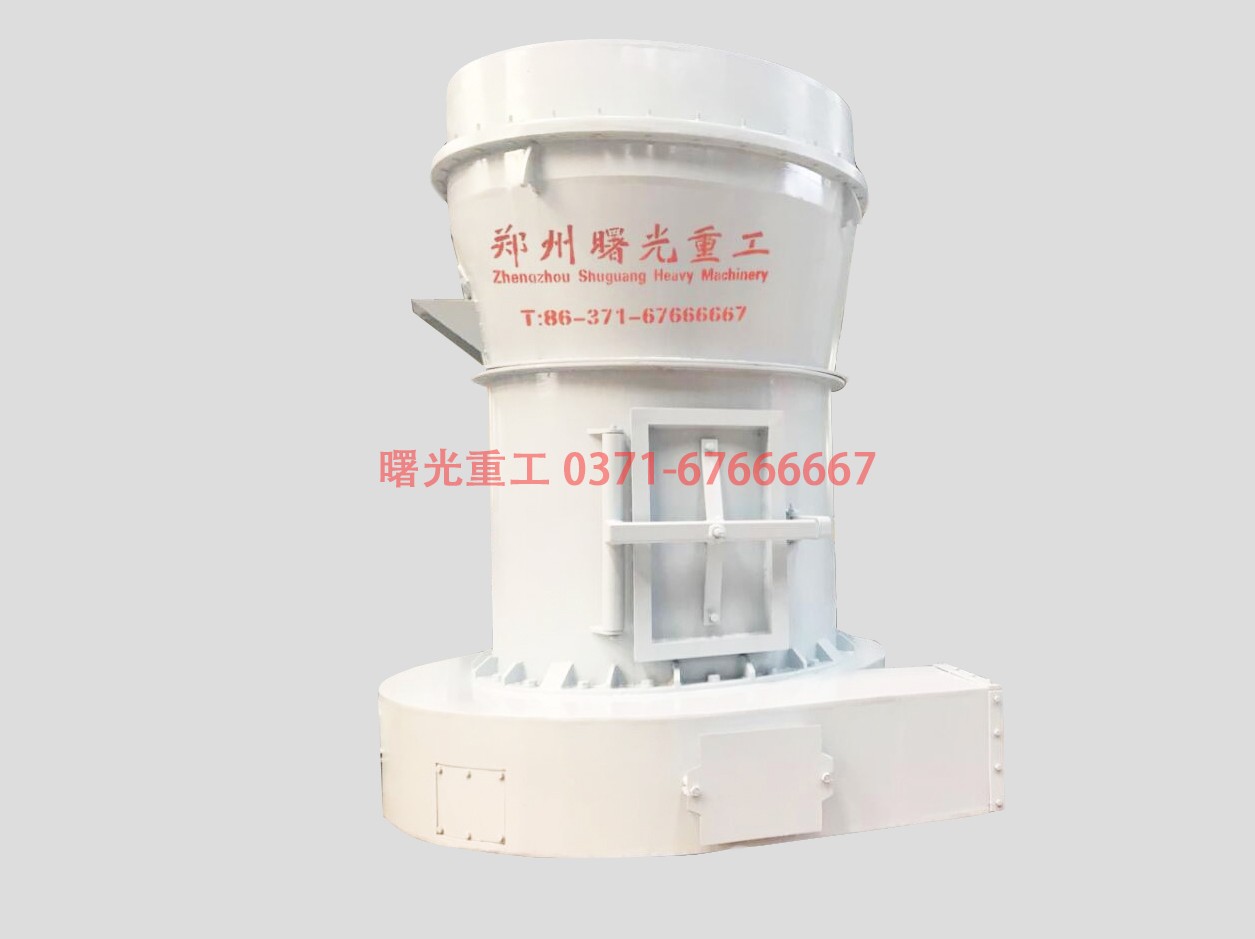

Product details

Calcium carbonate grinding mill is for super-fine grinding materials with hardness less than 6 in Moh‘s scale and humidity less than 6 percent such as kaolin, limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds.

Calcium carbonate grinding mill, the granularity (or final size) of the finished products can be freely adjusted between 500-2500meshes (0.025-0.005mm), and the capacity (ton/hour) ranges from 0.4T/H to 12T/H depending on the final size and the grinding materials.

Working Principle

1.The crusher will crush the big materials into small ones, and then the elevator will send them to the hopper.

2.The vibrating feeder will send the materials to the middle of first dial evenly.

3.The motor of main equipment drives the main shaft and dial through reducer, and the dial drives numbers of rollers moving in the ring channels via pins.

4.The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings.

5.The high pressure centrifugal blower will inhale air from outside and bring the crushed materials to classifier.

6.The rotating turbo in the powder collector will make the coarse materials return to the mill and regrounded, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it.

7.The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

After being ground,the qualified powder is selected by Separator via the cycle wind of the blower and the rough powder will be back to the grinding room for regrinding. The qualified powder is brought into the powder collector by airflow. The powder comes out as end products.

Features

1. The structure of calcium carbonate grinding mill is tight, from crushing to grinding and packing all together forms an independent production system, it has advantages of covering small area, operating simple, saving work force.

2. The final product has high passing screen ratio, which can achieve 99%.

3. Driving system of main frame adopts airtight gearing and pulley, which secures reliable operation.

4. Main parts of the grinding plant are made from cast and high quality steel, which ensures the durability of whole plant.

5. With application of centralized controlling electric control system, no operator is in the operating room.

Technical Data

|

Type |

unite |

7826 |

8327 |

8630 |

9732 |

|

Roller number |

a |

3 |

3 |

3 |

4 |

|

Roller diameter |

mm |

Ø260 |

Ø270 |

Ø300 |

Ø320 |

|

Grinding ring inner diameter |

mm |

Ø780 |

Ø830 |

Ø860 |

Ø970 |

|

Main engine speed |

R/min |

160 |

160 |

155 |

140 |

|

Max. Feeding size |

mm |

|

|

|

|

|

output |

T/h |

0.25-2 |

0.3-3 |

1-4 |

2-7 |

|

Main engine motor type |

kw |

Y225S-8-18.5 |

Y225M-8-22 |

Y225M-8-22 |

Y225S-8-37 |

|

Fan Motor Type |

kw |

Y160L-4-15 |

Y180M-4-18.5 |

Y180M-4-18.5 |

Y200L-4-30 |

|

Analysis Machine Motor Type |

kw |

YCT1604B-2.2 |

YCT160-4B-3 |

YCT160-4B-3 |

YCT200-4A-5.5 |

|

Total power |

kw |

37.5 |

44.5 |

44.5 |

72.5 |

|

Length*width*height |

m |

4.5*4.2*5.1 |

5.3*4.1*5.2 |

5.5*4.5*5.6 |

7.1*5.9*7.9 |

|

weight |

t |

3.6 |

4.0 |

4.5 |

11.5 |

|

Fineness |

mesh |

500-2500 |

500-2500 |

500-2500 |

500-2500 |

Previous page:Bauxite grinding mill for sale

Next page:Construction Waste Sorting Machine

TEL:0086-13523465141

0086-371-67666660

FAX:0086-371—68125111

Email:shuguang_mill@163.com

Address:No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China